Last week on the blog we discussed hot oil heaters and some of the reasons why you might use one instead of heating something directly. This week we want to look at how hot oil heaters are different than another similar option – steam heating. Just like a hot oil system, steam can be heated inside a heater and used to warm up a secondary fluid in another piece of equipment. There are many people that use steam for heating, but the numbers seem to be decreasing as the use of thermal fluids are becoming more common. Why are thermal fluid systems replacing steam systems? Let’s take a look at a few of the major advantages of a thermal fluid system over a steam system:

1. Safety

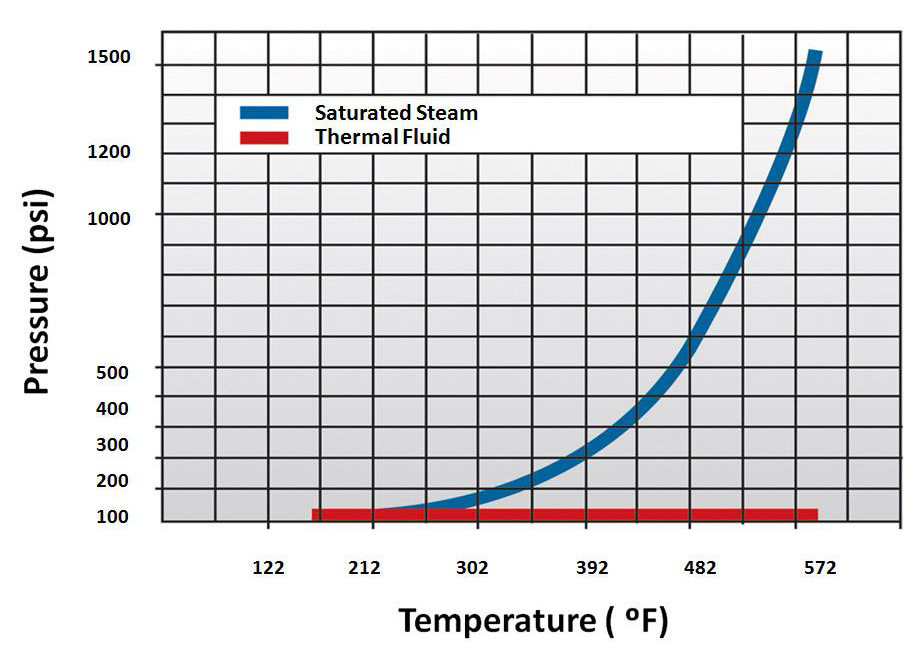

To get higher temperatures using a steam system, the overall system must be kept at high pressures. As you can see from the chart below, to reach a temperature of around 525 °F, the steam must be at approximately 900 psig. Operating at high pressures represents potential safety hazards in a facility, and many states and jurisdictions require special permitting to operate.

As you can also see from the chart, thermal fluids do not suffer from this drawback. They can operate a minimum pressure all the way through the temperature range. Being able to operate at lower pressures minimizes the safety risk at a facility.

2. Efficiency

In general steam systems are less efficient overall when compared to thermal fluid systems. Losses occur throughout the steam system, including:

- Flash loss – can be 6-14% (including trap losses)

- Blowdown loss – can be up to 3%

- De-Aerator loss – can be up to 2%

Thermal fluid systems do not suffer from the above losses. Greater efficiency means more money back in your pocket! And who doesn’t like that?!

3. Maintenance

System maintenance is not always the first thing people think about when they buy a piece of equipment or complete system, but there are times when it plays a critical part in the decision making process. Steam systems require regular maintenance on various components of the system:

- Steam traps

- Valves

- Condensate return pumps

- Expansion joints

- Water analysis

- Water treatment

Steam systems also have the concern of potential freezing in cold weather. Thermal fluid systems don’t have this risk, and don’t contain many of the same components requiring maintenance – traps, condensate return, blowdown or water additives. There are still items in a thermal fluid system that need maintenance to ensure long life, but not as many as in a steam system.

Also, because of the properties of the steam, as well as the additives in the steam, it is more likely to corrode the process piping as compared to a thermal fluid.If you would like to read a little more on the topic, Paratherm has a nice resource on the topic as well.

Need a hot oil heater for your project? Check out heater and auxiliary equipment options!

Stay tuned to the blog all month as we talk about hot oil heaters and design considerations. We will also be giving away a free tool at the end of the month, so make sure to check it out.

Sign up on the right side to make sure you never miss a post!