If you are like me, the controls side of the equipment is a weak area in your knowledge set. And while we can’t fix that in just a couple of blog posts, we are going to try and cover some high level topics as they relate specifically to heaters. All month long we will cover various topics related to controls and instrumentation used in heater applications.

The first topic we are going to cover is “area classifications”. What is an area classification? Why do you classify an area? And how do we protect ourselves in a classified area? Let’s dive in to find out some of these answers.

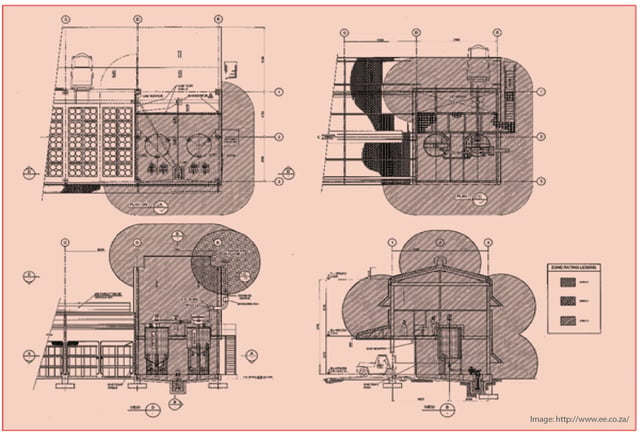

Area classifications are a way to specify the level of risk of explosion in a hazardous location. But what is considered a hazardous location? The NEC and CEC define a hazardous location as:

“An area where a potential hazard (fire, explosion, etc.), may exist under normal or abnormal conditions because of the presence of flammable gases or vapors, combustible dusts or ignitable fibers or flyings.”

We can use a common tool to help explain – the combustion triangle. For combustion (fire, explosion, etc) to occur, you need 3 things:

- An ignition source (fire, spark, etc)

- An oxidizer (air)

- And a flammable substance (or fuel)

If you have these items present, then the area is considered hazardous and should be classified as such. There are several governing bodies when it comes to area classifications, but the two most common are NFPA 70: NEC (National Electrical Code) and IEC (International Electrotechnical Code). The NEC is primarily used in the U.S. and the IEC is used most everywhere else, although they can be used anywhere. There are many other country or region specific codes, but most tend to fall in line with either NEC or IEC (or both).

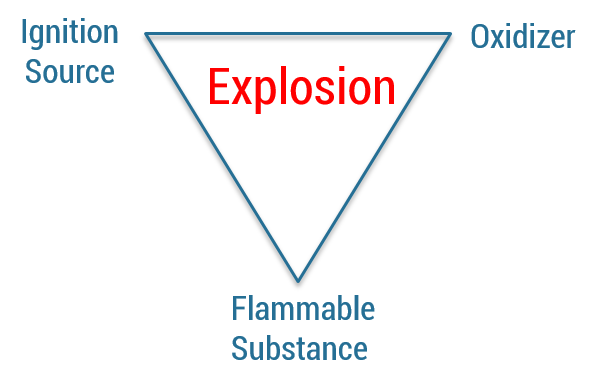

Let’s say you have an application that you believe requires the equipment to be considered inside a hazardous area. Now what? How do you reduce or eliminate the risks of fire and/or explosion? The first, and easiest way, to do it is to remove any of the 3 elements in the triangle from the area. The easiest one to remove is usually the ignition source. If there is no way to ignite the flammable substance and oxidizer, then you shouldn’t have a problem. One practical way to accomplish this is to move the electrical equipment away from the ignition source. How far away will depend on a number of circumstances, but in many heater applications we have seen users move the control panel more than 50 feet away from the heater in order to rate the panel as unclassified.

The other, maybe more common, method when you have equipment in a hazardous location is to buy electrical equipment and controls to meet the area classification required. Electrical components designed for hazardous locations are designed to confine, isolate, or limit their exposure to one or all of the elements of combustion. They can do this in a number of ways, including:

- Enclosing

- By enclosing the equipment you can limit its exposure to the ignition source or oxidizer

- Purging

- Uses positive air pressure to keep flammable vapors from entering an enclosure

- Sealing

- Sealing prevents an oxidizer or ignition source from reaching the potentially flammable substance

SOME EXAMPLES

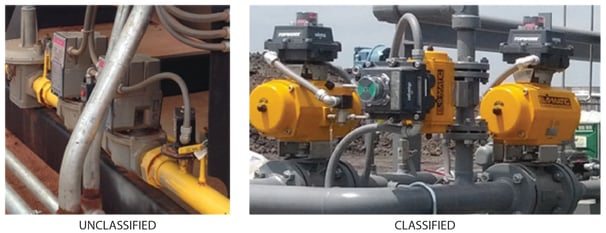

Valve components:

Control panels:

So if you can buy equipment rated for hazardous locations, and they provide a higher level of safety, why would you choose to use equipment that is not designed for hazardous locations?

- COST

- As with most things in life, if you want something that provides more value (in this case a higher level of safety), it costs more. Classified systems can run anywhere between 2 and 5 times more expensive than an unclassified system.

- AVAILABILITY

- Classified components typically have longer lead times, making your project schedule longer. Many unclassified components are available “off the shelf” and can be delivered in days.

That wraps up our discussion on area classifications. You can learn more about each area classification and when to use each of them by visiting www.nfpa.org and looking for the NFPA 70: NEC publication.

Still have questions? Feel free to contact us and we can try to help you get what you need.

Stay tuned all month as we discuss other electrical and controls topics related to heaters.